In industries where the risk of explosive atmospheres is constant, particularly in areas classified as ATEX Zone 1, the need for reliable and high-performance equipment is absolutely essential. The Dekra VT1000 pitting inspection camera is an advanced solution specifically engineered for these hazardous environments. With its Full HD resolution and powerful 30x optical zoom, this camera is built to provide crystal-clear, highly detailed imagery, ensuring that both safety and accuracy are upheld even in the most demanding conditions.

What sets the Dekra VT1000 apart is its cutting-edge technology and durable design, tailored to meet the rigorous standards required for ATEX Zone 1 compliance. In this discussion, we will delve into the camera’s standout features, its key advantages, and its practical applications. By understanding the technology behind the Dekra VT1000, professionals working in high-risk zones can better appreciate why this camera is regarded as a top-tier tool for ensuring operational safety and performance in explosive environments.

What Does ATEX Zone 1 Mean?

ATEX Zone 1 refers to an environment where an explosive atmosphere, created by a mixture of air and flammable gases, vapors, or dust, is likely to form occasionally during normal operations. These conditions are often found in industries like oil and gas, chemical manufacturing, and pharmaceuticals. In such high-risk areas, it is crucial to use equipment that complies with stringent safety regulations to prevent ignition and ensure operational safety. Devices used in ATEX Zone 1 must be specifically designed and certified to handle the potential hazards posed by these volatile environments.

The Significance of Specialized Cameras in ATEX Zone 1

In ATEX Zone 1, where safety is paramount, even the smallest mistake can lead to dangerous or catastrophic incidents. Standard cameras are not suitable for these settings because they pose risks such as generating heat or sparks, which could ignite the surrounding explosive atmosphere. As a result, specialized equipment is essential to ensure safe and efficient operations.

The DEKRA VT1000 camera is specifically designed to address the unique challenges of ATEX Zone 1 environments. Built to meet stringent safety requirements, this camera incorporates advanced features that reduce risk and enhance safety. With its durable construction and precision engineering, the DEKRA VT1000 enables critical visual inspections without jeopardizing the safety of the environment. Offering clear, high-quality images, it is a reliable tool for maintaining both safety and operational efficiency in hazardous conditions.

The Necessity of Specialized Cameras

In ATEX Zone 1 environments, where safety risks are extremely high and there is little room for error, standard cameras are unsuitable due to their potential to produce sparks or heat that could trigger an explosion. The DEKRA VT1000 is specially engineered for use in these hazardous conditions, ensuring that essential visual inspections can be performed without compromising safety. Designed to meet stringent safety requirements, this camera minimizes the risk of ignition while providing reliable performance in volatile settings.

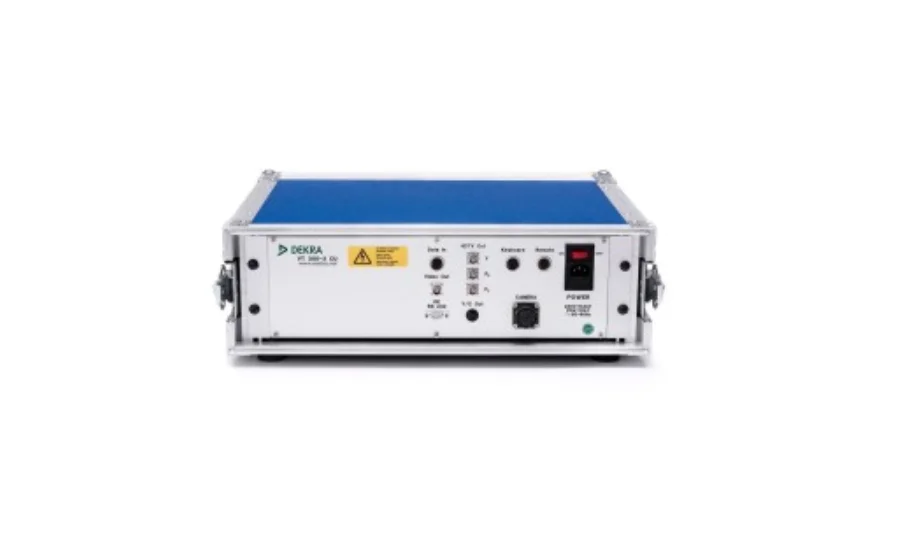

Key Features of the DEKRA VT1000

Full HD Imaging for Superior Clarity: The DEKRA VT1000 features a Full HD camera that provides exceptionally clear images and videos. This high-definition capability is essential in environments where precision and detail are crucial for ensuring safety. Whether you’re inspecting equipment, overseeing processes, or documenting conditions, the DEKRA VT1000 delivers the visual clarity needed for accurate evaluations.

30x Optical Zoom for Enhanced Detail: A notable advantage of the DEKRA VT1000 is its 30x optical zoom, which enables detailed inspections from a distance without compromising image quality. This zoom feature is particularly valuable in hazardous environments where close proximity might be unsafe. It allows operators to focus on intricate details and inspect hard-to-reach areas or active machinery effectively.

Built for Durability and Reliability: Designed to endure the demanding conditions of ATEX Zone 1, the DEKRA VT1000 is constructed from durable materials that resist corrosion, extreme temperatures, and physical shocks. This robust design ensures the camera remains operational and reliable, even under severe conditions, minimizing the need for frequent maintenance or replacements.

Intuitive Controls for Easy Operation: Given the challenges of working in hazardous environments, the DEKRA VT1000 is equipped with a user-friendly interface and straightforward controls. This design facilitates quick adjustments and efficient image capture, which is crucial in high-pressure scenarios where rapid response is necessary.

ATEX Compliance for Safe Operation: In ATEX Zone 1, safety is paramount, and the DEKRA VT1000 adheres to all relevant ATEX standards. Its certification for use in explosive atmospheres ensures that it is safe from risk of ignition, providing users with confidence that they are employing equipment designed to meet the highest safety requirements.

Maximizing the Efficiency of the DEKRA VT1000

Comprehensive Operator Training: To fully utilize the capabilities of the DEKRA VT1000 pitting inspection camera, it is vital that operators receive thorough and in-depth training. This training should cover key aspects such as mastering the camera controls, positioning techniques for optimal imaging angles, and interpreting the high-definition images and videos it captures. Operators should also be well-versed in adjusting the camera settings to maximize image clarity and detail. By providing operators with detailed training on all the camera’s features, companies can ensure more accurate inspections and heightened safety. Continuous training is an investment that not only improves the efficiency of the camera but also enhances overall operational performance.

Continuous Upkeep and Adjustment: The DEKRA VT1000 is made to withstand harsh conditions, but in order to keep it operating at its best, it needs to be periodically calibrated and maintained. Important maintenance activities include making sure the zoom function works smoothly, checking that all seals and connectors are tight, and keeping the lens clean to prevent any distortion of the image caused by dust or debris. Frequent calibration contributes to ensuring that the camera keeps producing dependable and precise photos. Following a maintenance schedule will increase the camera’s longevity, guarantee constant image quality, and reduce the possibility of malfunctions. Maintaining the camera properly is essential to making sure it continues to be a trustworthy instrument for precise examinations throughout time.

System Integration for Enhanced Functionality: For organizations that utilize multiple monitoring and inspection tools, integrating the DEKRA VT1000 with other systems can significantly boost its effectiveness. By combining visual data from the camera with input from other technologies, such as sensors or data analytics platforms, companies can gain a more comprehensive understanding of the environment being monitored. This integration allows for more detailed assessments and better-informed decision-making. Aligning the camera with existing systems enhances situational awareness, enabling operators to analyze data from multiple sources simultaneously, leading to more accurate conclusions and improved management of hazardous environments. This holistic approach strengthens overall safety and operational efficiency.

Advantages of the DEKRA VT1000

Enhanced Safety: The DEKRA VT1000 significantly boosts safety in hazardous environments by allowing inspections and monitoring from a safe distance. This feature reduces the need for personnel to enter potentially dangerous areas, thereby lowering the risk of accidents and injuries. By minimizing direct exposure to hazardous conditions, the DEKRA VT1000 helps ensure compliance with stringent safety regulations and supports a safer work environment.

Increased Efficiency: Engineered to enhance operational efficiency, the DEKRA VT1000 streamlines the inspection and monitoring processes with its advanced imaging capabilities. The camera captures high-resolution images and videos swiftly, facilitating quicker identification of issues and more rapid decision-making. This increased efficiency reduces the time and resources needed for inspections, leading to cost savings and improved accuracy in data collection.

The camera’s durable construction ensures longevity and reduces the need for frequent repairs, which lowers maintenance costs. Furthermore, its ability to operate safely in explosive environments helps avoid costly accidents and operational interruptions. Over its lifecycle, the DEKRA VT1000 offers significant financial advantages, making it a prudent investment for industries with high safety and operational standards.

Versatility Across Industries: The DEKRA VT1000 is highly versatile and suitable for a wide range of sectors, including oil and gas, pharmaceuticals, and chemical processing. Its ability to deliver high-quality imaging in hazardous conditions makes it an essential tool for various applications, from routine inspections to emergency response. This versatility ensures reliable performance across different industries, enhancing overall operational effectiveness and precision

Uses of the DEKRA VT1000

Industrial Inspections: In industries like oil and gas, where maintaining safety and efficiency through regular inspections is crucial, the DEKRA VT1000 plays a vital role. Its Full HD camera and 30x optical zoom enable thorough examinations of equipment, pipelines, and infrastructure from a safe distance. This is particularly valuable in environments where direct access to machinery is restricted due to safety considerations, allowing inspectors to perform their tasks effectively without compromising safety.

Process Monitoring: The DEKRA VT1000 excels in monitoring industrial processes, especially in ATEX Zone 1 environments where ongoing supervision is necessary to ensure smooth operation and detect any potential issues. Its high-definition video capabilities provide operators with detailed views of critical processes, helping to identify and address problems before they escalate, thereby ensuring the stability and safety of operations.

Emergency Response: In emergency situations such as gas leaks or equipment failures, the DEKRA VT1000 proves to be an invaluable asset. Its robust design and certification for use in explosive atmospheres allow it to gather essential visual information quickly and safely. This capability supports emergency responders in assessing and addressing dangerous situations without putting themselves at risk.

Research and Development: For research and development teams working in hazardous settings, the DEKRA VT1000 offers crucial visual documentation. Its ability to capture high-quality images and videos aids in detailed analysis and experimentation. Whether for recording experiments or analyzing new technologies, the camera’s advanced imaging features provide the clarity needed for thorough investigation and development.

How to Get the Most Out of the DEKRA VT1000

Effective Training for Operators: To fully leverage the capabilities of the DEKRA VT1000, it’s crucial that operators receive thorough training. This training should cover the operation of the camera’s controls, optimal positioning techniques for clear viewing, and methods for accurately interpreting the captured images and videos. Investing in detailed training programs ensures that operators can use the camera efficiently and maximize its potential.

Ongoing Maintenance and Calibration: Although the DEKRA VT1000 is designed for robustness, consistent maintenance and calibration are important to maintain its peak performance. Regular tasks should include cleaning the camera lens to avoid image distortion, inspecting the zoom mechanism for smooth operation, and checking the integrity of seals and connectors. Adhering to a regular maintenance schedule will not only prolong the camera’s life but also ensure it consistently delivers high-quality visuals.

System Integration: For organizations utilizing various monitoring and inspection tools, integrating the DEKRA VT1000 with existing systems can significantly enhance its functionality. Combining the visual data from the camera with information from other monitoring technologies allows for a more comprehensive analysis. This integrated approach provides a fuller picture of the monitored environment, facilitating better data interpretation and decision-making.

Outstanding Imaging and Resilience in Hazardous Conditions

The DEKRA VT1000 boasts Full HD imaging technology, delivering exceptional clarity that is vital for operations in hazardous environments. This high-definition capability ensures precise visual detail, which is crucial for maintaining safety and ensuring effective operations in areas with explosive risks. Industries such as oil and gas, chemical processing, and pharmaceuticals greatly benefit from the clear and accurate visuals provided by the DEKRA VT1000. This clarity helps operators make well-informed decisions, whether they are inspecting complex machinery, monitoring intricate processes, or documenting environmental conditions in real-time.

A key feature of the DEKRA VT1000 is its powerful 30x optical zoom. This feature allows for detailed close-up inspections from a safe distance without compromising image quality. This is particularly valuable in dangerous environments where direct access to certain areas may be restricted. By enabling operators to capture detailed images of hard-to-reach or risky locations, the DEKRA VT1000 enhances operational efficiency while minimizing personnel risk. Its ability to produce high-quality visual data is crucial for accurate assessments and decision-making.

Built to withstand the severe conditions of ATEX Zone 1, the DEKRA VT1000 is engineered with durability in mind. It is constructed from robust materials that resist corrosion, extreme temperatures, and mechanical shocks. This rugged design ensures that the camera remains reliable and functional even in the most challenging environments, reducing the need for frequent repairs or replacements. Such resilience is essential for maintaining safety and operational continuity, making the DEKRA VT1000 a trusted choice for professionals working in hazardous settings.

The DEKRA VT1000 also features an intuitive user interface that simplifies operation in high-pressure situations. Its easy-to-use controls allow for quick adjustments and image capture, which is critical when time is of the essence. This user-friendly design not only reduces the learning curve for new operators but also enhances overall efficiency, making the camera effective in urgent or demanding scenarios.

Meeting all relevant ATEX safety standards, the DEKRA VT1000 is certified for use in explosive atmospheres, ensuring it operates without any risk of ignition. This adherence to safety regulations provides users with confidence in the camera’s reliability and suitability for hazardous conditions, reinforcing its role as a safe and effective tool in critical environments.

Unlocking the Full Potential of DEKRA VT1000 Images

To fully utilize the DEKRA VT1000 and maximize its capabilities, operators must undergo thorough training. This training should cover the effective use of the camera’s controls, techniques for positioning it to achieve the best viewing angles, and methods for accurately interpreting the detailed images and videos it produces. A well-structured training program ensures that operators can harness the full potential of the DEKRA VT1000, leading to more precise inspections and improved safety outcomes.

Regular maintenance and calibration are vital for maintaining the DEKRA VT1000’s performance and extending its lifespan. Despite its durable construction, the camera requires ongoing care to function at its best. This involves routine tasks such as cleaning the lens to avoid image distortion, inspecting the zoom mechanism to ensure smooth operation, and checking that all seals and connectors are secure. Proper maintenance not only enhances the camera’s reliability but also ensures it continues to deliver high-quality imagery over time.

Integrating the DEKRA VT1000 with other monitoring and inspection systems can greatly amplify its effectiveness. By combining the camera’s high-definition visuals with data from additional sources, users gain a more comprehensive understanding of the monitored environment. This integration facilitates more detailed data analysis and provides a holistic view of the situation, which can enhance operational efficiency and effectiveness.

Also Read: G40 1150 2jzgte vvti spool

Final Words

The DEKRA VT1000 is a specialized pitting inspection camera designed for use in ATEX Zone 1 hazardous environments. Engineered for safety and durability, it provides Full HD imaging with a powerful 30x optical zoom, enabling detailed inspections without compromising image quality or safety. Its robust design ensures reliable operation in extreme conditions, such as those found in the oil, gas, chemical, and pharmaceutical industries. The camera is certified to meet stringent ATEX standards, minimizing risks in explosive atmospheres. With intuitive controls and easy maintenance, the DEKRA VT1000 is a trusted tool for enhancing safety, operational efficiency, and precision in high-risk environments.

Find your perfect pair by visiting Alevemente today.